Prefabricated Homes – Affordable and Efficient Housing Options with Fast Installation

Prefabricated homes represent a revolutionary approach to residential construction, offering homeowners a faster, more cost-effective alternative to traditional building methods. These factory-built structures combine quality craftsmanship with streamlined production processes, delivering complete housing solutions that can be assembled on-site in a fraction of the time required for conventional construction.

The housing market continues to evolve with innovative construction methods that address affordability, efficiency, and sustainability concerns. Prefabricated homes have emerged as a compelling solution for Canadian homeowners seeking quality housing without the extended timelines and unpredictable costs associated with traditional construction methods.

What Are Prefabricated Homes and How Do They Work?

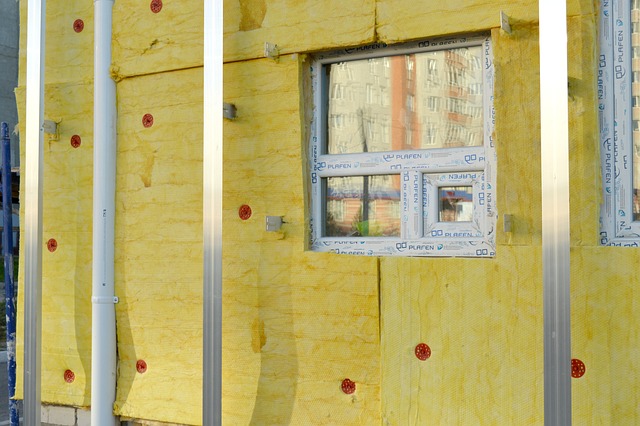

Prefabricated homes are residential structures manufactured in controlled factory environments before being transported and assembled at their final location. The construction process involves creating standardized components or entire sections in climate-controlled facilities, ensuring consistent quality and precise measurements. Factory workers assemble walls, floors, roofing systems, and other structural elements using specialized equipment and quality control measures that exceed typical on-site construction standards.

The manufacturing process typically takes 6-12 weeks, depending on the home’s complexity and customization level. Once completed, sections are transported via truck to the building site, where foundation work has been prepared in advance. Professional installation teams then assemble the components, connect utilities, and complete finishing work, often within days rather than months.

How Do Efficient Prefabricated Homes Compare to Traditional Construction?

Efficient prefabricated homes offer several advantages over conventional building methods. Construction timelines are significantly reduced, with total project completion often occurring within 3-4 months compared to 8-12 months for traditional builds. Weather delays are minimized since most construction occurs indoors, and material waste is substantially reduced through precise factory cutting and standardized processes.

Energy efficiency represents another key advantage, as factory-controlled environments allow for superior insulation installation, tighter building envelopes, and consistent quality control. Many prefabricated homes exceed energy efficiency standards required by local building codes, resulting in lower utility costs and improved comfort for residents.

What Types of Prefabricated Home Designs Are Available?

Prefabricated home designs span a wide range of architectural styles and sizes, from compact single-story units to expansive multi-level family homes. Modular designs allow for customization through various floor plans, exterior finishes, and interior configurations. Popular styles include contemporary designs with clean lines and large windows, traditional layouts reminiscent of conventional homes, and specialized designs for specific climates or lot configurations.

Manufacturers offer extensive customization options including kitchen layouts, bathroom configurations, flooring materials, and exterior siding choices. Some companies provide fully customizable designs, while others focus on optimized standard plans that balance cost-effectiveness with popular features.

How Do Zoning Laws and Building Codes Affect Prefab Installation?

Zoning laws and building codes significantly impact prefabricated home installation across Canadian municipalities. Most jurisdictions treat prefabricated homes identically to site-built structures, requiring compliance with local building codes, setback requirements, and architectural guidelines. However, some areas maintain restrictions on manufactured homes or require specific foundation types that may affect installation costs.

Prospective buyers should research local regulations early in the planning process, as some communities have minimum square footage requirements, architectural review processes, or restrictions on certain prefabricated home types. Working with experienced local contractors and manufacturers familiar with regional requirements helps ensure smooth approval and installation processes.

Real-World Cost Insights for Prefabricated Homes

Prefabricated home costs vary significantly based on size, customization level, and regional factors. Understanding typical pricing structures helps potential buyers make informed decisions about this housing option.

| Home Size | Base Cost Range | Installation Cost | Total Estimated Cost |

|---|---|---|---|

| 1,000 sq ft | $80,000-$120,000 | $15,000-$25,000 | $95,000-$145,000 |

| 1,500 sq ft | $120,000-$180,000 | $20,000-$35,000 | $140,000-$215,000 |

| 2,000 sq ft | $160,000-$240,000 | $25,000-$40,000 | $185,000-$280,000 |

| 2,500 sq ft | $200,000-$300,000 | $30,000-$50,000 | $230,000-$350,000 |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Additional costs include site preparation, foundation work, utility connections, and permits, which typically add $20,000-$50,000 to total project expenses. Transportation costs depend on distance from manufacturing facilities, while customization options can increase base prices by 15-30%. Many manufacturers offer financing options, and some prefabricated homes qualify for conventional mortgages similar to traditional construction loans.

Prefabricated homes continue gaining acceptance as a viable housing solution, offering Canadian homeowners an efficient path to homeownership with reduced construction timelines and predictable costs. The combination of factory precision, energy efficiency, and design flexibility makes these homes an attractive option for various housing needs and budgets.